🧈 Introduction – Why Do Fats and Oils Matter in Cookies?

If you’ve ever wondered why one batch of cookies turns out thin and crisp while another stays thick and chewy the answer often lies in a single ingredient: fat.

Fats and oils in cookies do far more than make them taste rich. They shape texture, spread, aroma, mouthfeel, and even shelf life. From the soft bite of a chocolate chip cookie to the snap of a shortbread, every crumb tells a story of how the fat inside behaved during baking.

In simple terms, fats control how cookies form and feel:

- 🌀 Spread: How wide the dough flows before setting

- 🍪 Texture: Whether the cookie turns crisp, tender, or chewy

- 🌸 Flavor release: Butter and milk fats enhance aroma compounds

- 🕒 Freshness: The right fat helps cookies stay moist and pleasant longer

That’s why the function of fat in cookies goes far beyond flavor — it’s the structural backbone of your recipe. Just like eggs influence structure and binding in cookies, fats define texture, spread, and mouthfeel. Every ingredient—from sugar and butter to salt and flour—works together to shape your cookie’s final character.

🧭 From Home Kitchens to Cookie Factories

Home bakers might reach for butter out of habit, but professional cookie manufacturers think in terms of fat performance. They choose between butter, shortening, margarine, and specialty bakery oils based on melting point, plasticity, flavor profile, and shelf stability.

💡 With over 17 years of hands-on experience in the baking industry, I’ve seen firsthand how small changes in fat type can completely transform a cookie’s structure and flavor. In commercial bakeries, fat isn’t just an ingredient — it’s an engineering component. The right choice ensures consistent texture across thousands of cookies baked every hour.

As we explore further, you’ll see how different fats and oils — from butter and margarine to spray fats used in cookie factories — each play a specialized role in shaping cookie texture, flavor, and quality.

🧬 What Is the Science Behind Cookie Fats?

If flour builds the structure of cookies, fat decides how that structure feels in your mouth. Behind every chewy, crumbly, or crisp bite lies the science of fat composition — a balance of solid and liquid phases, fat crystals, and melting behavior that shape the final texture.

⚖️ Fat Structure and Composition

Cookie fats are made up of triglycerides, molecules built from fatty acids that can be either saturated (solid at room temperature) or unsaturated (liquid at room temperature).

- Saturated fats — like butterfat, shortening, and coconut oil — have a higher melting point, allowing them to hold air during creaming.

- Unsaturated fats — like vegetable or canola oil — stay liquid and don’t trap air, which leads to flatter, denser cookies.

This difference explains why butter-based cookies tend to spread more but taste richer, while shortening-based cookies hold shape and stay soft longer.

🧈 Fat Crystallization and Plasticity

When a fat cools from its liquid state, it forms crystals — tiny solid structures within the fat. These crystals determine how the fat behaves during mixing and baking.

- A fat with fine, uniform crystals feels smooth and pliable — bakers call this a plasticized fat.

- A fat with large crystals feels hard and grainy, making it difficult to cream with sugar or blend evenly into dough.

In cookie production, plasticity (the balance between solid and liquid fat phases) is crucial. It affects:

- 🍪 Dough texture: Smooth, plastic fats create pliable dough that mixes easily.

- 🌀 Aeration: Fats with fine crystals trap more air, giving cookies a light, tender crumb.

- 🌡️ Spread control: The melting point of the fat determines how much cookies expand before setting.

Butter’s fat crystal structure plays a huge role in aeration and spread. If you’ve ever wondered what butter really does in cookies, its unique balance of solid and liquid fats explains why it creates that perfect golden edge and chewy center.

🏭 Industrial Perspective: Controlling Crystal Form

In professional bakeries and factories, controlling fat crystal form isn’t left to chance.

The solids content and crystal size of bakery fats are monitored closely at the time of use. These depend on ambient temperature and how the fat was cooled from its liquid state.

💡 If a fat is cooled too slowly or stored at inconsistent temperatures, large crystals can form — reducing plasticity and making the fat harder to work with.

That’s why industrial fats often undergo specialized processing to create a consistent crystal structure. Equipment such as votators or scraped-surface heat exchangers are used to produce perfectly plasticized fats optimized for cookie dough mixing lines.

In short, cookie texture begins long before baking — it starts with how the fat was processed, cooled, and handled.

🧠 How Do Fats Functionally Impact Cookie Dough and Texture?

If flour provides structure and sugar adds sweetness, fat is what gives cookies their soul — that irresistible tenderness, spread, and melt-in-the-mouth feel. To understand why fats are so important, let’s look at how they behave inside cookie dough at the molecular level.

⚙️ 1. Tenderness and “Shortening” Effect

When cookie dough is mixed, there’s a natural competition for the flour surface between water (or sugar syrup) and fat.

- Water activates gluten-forming proteins (gliadin and glutenin), creating a stretchy network.

- Fat, on the other hand, coats the flour particles and interrupts gluten development, leading to a softer, more tender bite.

That’s why bakers call fats “shortening agents” — they shorten the gluten strands, giving cookies a delicate, crumbly texture instead of a tough or bread-like chew.

💡 Pro Insight (from 17 years in baking):

In high-fat doughs, you can often reduce or eliminate water entirely — the dough still binds beautifully. These “short” doughs bake into cookies that crumble gently rather than stretch.

🍪 2. Spread and Dough Consistency

The melting point of the fat determines how much cookies spread in the oven:

- Low-melting fats like butter begin to liquefy early, causing wider spread and thinner cookies.

- Higher-melting fats like shortening hold their structure longer, resulting in taller, softer cookies.

Temperature also plays a major role — warm dough or overmixed fat melts prematurely, destroying the creamed air pockets that control spread.Too much fat—or using warm dough—can make cookies spread too much on the pan, while too little can leave them hard or dry.

⚠️ Mixing Tip: Overmixing or working dough when the fat is too warm breaks down fat crystals, leading to poor aeration and uneven spread.

🌬️ 3. Aeration and Texture

Solid fats (butter, shortening, margarine) can trap air during the creaming process — this is key to creating light, tender cookies.

Oils, however, are liquid and cannot hold air, so oil-based cookies are denser, more cake-like, and less crisp.

In industrial production, fat aeration is carefully controlled by adjusting mixing speed, temperature, and crystal form, ensuring each batch has the same structure and mouthfeel.

💧 4. Moisture Retention and Chewiness

Fats also act as moisture barriers. They coat starch granules and proteins, slowing down water loss during baking and storage.

This helps cookies stay soft and chewy instead of drying out.

In high-sugar recipes, fats combine with syrupy sugar solutions during baking to form a toffee-like matrix, preventing the cookie from hardening on cooling — a secret behind that luscious chewy center.

🍫 5. Flavor Enhancement and Browning

Butter contributes hundreds of natural flavor compounds and promotes Maillard browning, giving cookies their signature aroma and golden color.

Margarine and shortening can also carry flavors but are often neutral; industrial bakers sometimes blend butter or butter oil with these fats for a richer sensory profile.

🏭 6. Industrial Applications of Fats in Cookie Systems

In large-scale bakeries, fats aren’t limited to doughs — they play multiple roles:

- 🧁 Dough fats: control texture and machineability

- 🍬 Cream fats: create smooth fillings and coatings

- ✨ Spray or release fats: prevent sticking on oven bands or add post-bake shine

💡 Industrial perspective: In automated lines, maintaining consistent fat plasticity and temperature ensures stable dough handling, uniform spread, and predictable bake results — every cookie, identical to the last.

In short, the function of fat in cookies goes beyond flavor — it’s a precise balance of chemistry and craftsmanship. Understanding how fat interacts with flour, sugar, and temperature gives bakers the power to engineer texture, chewiness, and spread to perfection.

Managing fat temperature and dough consistency also prevents issues like cookies burning on the bottom, ensuring even baking.

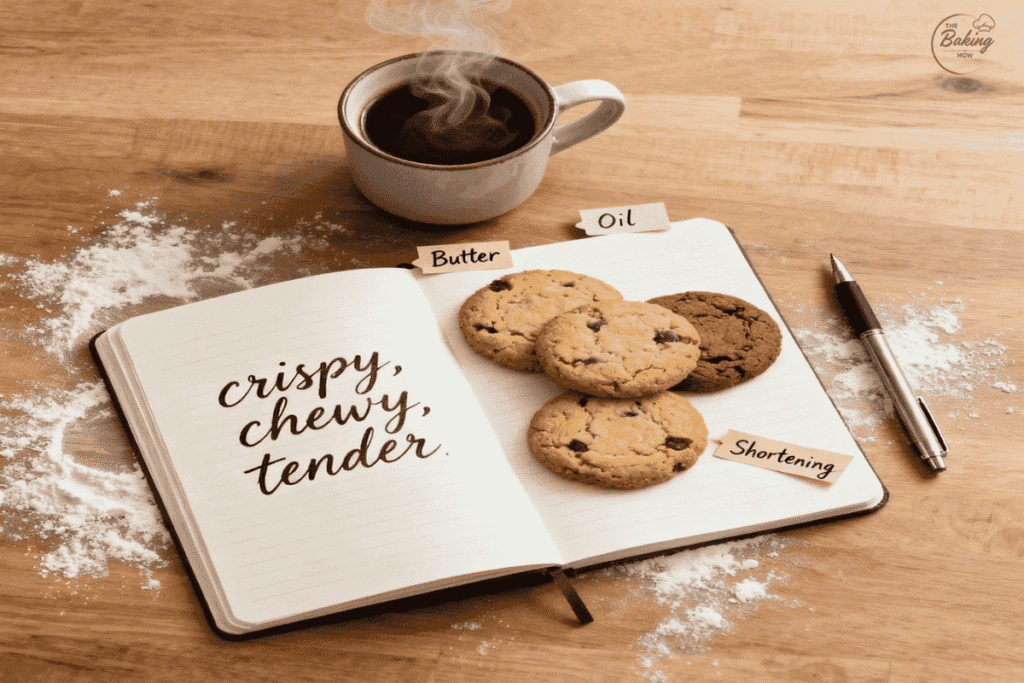

🧈 What Types of Fats and Oils Are Used in Cookies?

Not all fats are created equal. The type of fat you choose — butter, shortening, margarine, or oil — can completely change your cookie’s texture, flavor, spread, and even shelf life. In professional baking, the selection of fat is a calculated decision based on performance, plasticity, and cost-efficiency.

Drawing from my 17 years of experience in the baking industry, here’s how each type behaves, both in home and industrial cookie production 👇

🧈 3.1 Butter — The Gold Standard of Cookie Flavor

Butter is both a flavor powerhouse and a functional fat. It’s about 80–82% milk fat, with roughly 16% water and small amounts of milk proteins. That moisture content helps cookies spread more, resulting in thinner, crispier edges and rich aroma.

🔬 Composition and Baking Behavior

- Low melting point: Butter melts early during baking, creating that signature cookie spread.

- Flavor chemistry: During baking, butter undergoes the Maillard reaction and mild caramelization, producing buttery, toffee-like notes that pair beautifully with sugar and vanilla.

- Natural emulsifier: Its milk solids and water help bind ingredients during mixing.

💡 Professional insight: In commercial settings, butter’s natural variation — due to season, origin, and lactic processing — can affect dough consistency and flavor intensity. Industrial bakeries often test each batch for uniform performance.

🧈 Butter Oil (Anhydrous Milk Fat)

Some factories use butter oil, which is pure milk fat without water or proteins. It offers:

- Longer shelf life

- Higher heat stability

- Easier bulk handling

However, butter oil lacks the full flavor of natural butter, producing cookies that taste flatter or less aromatic.

👉 Difference summary:

| Property | Household Butter | Industrial Butter Oil |

| Water content | ~16% | <0.5% |

| Flavor | Rich, toffee-like | Mild, neutral |

| Texture impact | More spread | Controlled spread |

| Use | Home baking | Industrial lines |

🧑🍳 Tip: Some manufacturers use “denatured butter” — butter mixed with sugar — as a cost-effective alternative that retains some flavor while improving dough handling.

🏗️ 3.2 Shortening — The Texture Architect

Shortening is 100% pure fat, engineered for maximum plasticity (softness and spread control). Because it contains no water, it minimizes steam formation, leading to taller, softer, and more stable cookies.

⚙️ Why Shortening Works So Well

- Creates a short, crumbly dough by limiting gluten formation.

- Requires less water for the same dough consistency.

- Provides excellent aeration when creamed with sugar.

- Extends shelf life due to low oxidation rates.

Adding emulsifiers (like mono- and diglycerides) helps shortenings disperse evenly in dough, improving texture while reducing fat usage by up to 10%.

💡 Industry insight: Commercial bakeries often use shortening blends (palm + canola + emulsifier) to balance cost, texture, and spread control — ensuring every cookie looks identical on the tray.

🧈 3.3 Margarine — The Customizable All-Rounder

Margarine was originally created as a butter substitute, but modern margarines are tailor-made for different bakery applications.

🧪 Composition and Properties

- Roughly 80–84% fat and 16% water, similar to butter.

- Made from vegetable oils (soybean, palm, or sunflower) and emulsified for uniform consistency.

- Can be customized for melting point, firmness, and dough workability — giving bakeries precise control.

Because margarine is plasticized (processed to maintain smooth crystal structure), it mimics butter’s handling properties but can be stored longer and at slightly higher temperatures.

⚠️ Note: Industrial bakeries usually avoid water-based margarine to prevent moisture interference in dough formation. Instead, they use boxed plasticized fats that behave like shortening but with butter-like handling.

🥥 3.4 Oils (Vegetable, Coconut, and Beyond) — The Liquid Innovators

Liquid oils like sunflower, canola, or corn oil don’t cream with sugar because they lack solid crystals. This makes them unsuitable for traditional cookie aeration, resulting in denser, more cake-like cookies.

However, oils still have a place in modern baking, especially for health-conscious or vegan formulations.

🔬 Industrial Cooling and Plasticizing

In factories, bulk oils must often be cooled and plasticized before use. If used directly, warm liquid oil coats flour too quickly, disrupting dough structure.

To overcome this, bakers use scraped-surface heat exchangers, which rapidly cool the oil while continuously scraping the chilled surface — preventing large crystal formation.

💡 This process, called plasticizing, produces a semi-solid, pumpable fat at about 26°C, with small, uniform fat crystals ideal for cookie dough integration.

If the oil cools unevenly or is stored improperly, supercooling may occur — where the oil remains liquid but later crystallizes suddenly into a hard mass. Continuous agitation during storage prevents this.

🧪 Oil Blends in Modern Baking

To improve texture and manage costs, many large bakeries use oil blends, such as:

- Palm + sunflower oil (for balanced spread and shelf stability)

- Coconut + canola oil (for plant-based butter mimicry)

- Butter oil + vegetable oil (for enhanced flavor with lower cost)

🌱 Trend Insight: These blends allow companies to produce vegan, sustainable, or palm-free cookies that still deliver buttery mouthfeel and desirable texture.

✅ Key Takeaway:

Each fat has a unique role — butter delivers flavor, shortening ensures texture, margarine offers control, and oils introduce flexibility. The real artistry lies in understanding their behavior and blending them smartly to engineer the perfect cookie bite, whether you’re baking at home or producing thousands per hour.

🍪 A Quick Guide for Home Bakers: Butter vs. Shortening vs. Oil

| Fat Type | Texture Result | Best For |

|---|---|---|

| 🧈 Butter | Chewy with rich flavor, moderate spread | Classic chocolate chip or chewy cookies |

| 🥧 Shortening | Light, tender, less spread | Sugar cookies or molded shapes |

| 🫒 Oil | Soft, moist, slightly crumbly | Vegan or cake-style cookies |

💡 Tip: For balance, try blending ½ butter + ½ shortening — flavor + structure in one!

🧈 What Are Specialty Bakery Fats and How Are They Used in Industrial Cookie Production?

In home baking, we usually talk about butter or oil. But in industrial cookie production, fats become a whole science. Manufacturers rely on specially engineered bakery fats designed for consistency, efficiency, and long shelf life. These fats ensure every batch of cookies—whether 1 tray or 10,000—comes out with the same texture, spread, and flavor profile.

💡 With over 17 years in the baking industry, I’ve seen firsthand how small variations in fat temperature or plasticity can completely change a cookie line’s texture and quality.

🧊 4.1 Plasticised and Boxed Fats

Plasticised fats are semi-solid bakery fats that have been cooled and mechanically agitated to create fine, uniform fat crystals—a process called plasticising. This makes them smooth, stable, and predictable during mixing.

🔍 Why it matters:

- Ideal for automated dough lines—easy to handle and consistently soft.

- Stored around 18–23°C, where the fat stays plastic but doesn’t melt.

- Processed using scraped surface heat exchangers, ensuring even cooling and crystal control.

- Benefits: uniform mixing, consistent texture, faster production, lower contamination risk.

🧠 Pro Insight: When I worked with large-scale bakeries, we found that using well-plasticised fats reduced dough variability and improved cookie uniformity by up to 30%. Small crystal size = smoother dough texture.

🛢️ 4.2 Bulk Handling of Fats

In industrial bakeries, fats aren’t stored in tubs—they’re pumped through insulated pipelines from large heated tanks. These tanks keep oils at roughly 50°C to prevent solidification.

Factory Workflow at a Glance:

- 🛻 Oils arrive by tanker → sampled for quality → filtered and transferred to insulated tanks.

- 🌡️ Temperature controlled with water jackets (not electric heaters) to avoid oxidation.

- 🧹 Tanks have sloped floors to collect sediment; cleaned regularly to prevent rancidity.

- 💨 Some factories use nitrogen blanketing to protect oils from oxidation and extend shelf life.

⚙️ Real Experience: Even with these systems, I’ve seen bulk fats degrade within weeks if left unused. Industrial fat management is truly a race against rancidity.

🍪 4.3 Sandwich Cream Fats

These are the specialized fats used in sandwich cookies (like Oreos). Their job is to stay solid at room temperature but melt smoothly in the mouth—a tricky balance achieved through careful fat engineering.

Core Characteristics:

- Formulated with coconut oil or palm kernel oil, selectively hardened for hot climates.

- Short melting range → smooth texture and fast flavor release.

- Designed to resist fat bloom and maintain cream structure during storage.

👨🍳 From My Experience: Just a 2°C change in melting range can transform the cream’s mouthfeel from silky to waxy. Industrial fat selection is precision science.

✨ 4.4 Spray Oil Fats

Keywords: spray oil fats, biscuit coating fats, surface shine fats

To give cookies their appetizing sheen and maintain moisture, bakeries often spray a thin layer of fat right after baking.

Here’s how it works:

- Fats (often coconut or palm kernel oils) are heated and atomized into fine droplets.

- Applied while cookies are still warm to ensure adhesion.

- Creates a subtle gloss, improves mouthfeel, and prevents staling.

⚠️ Pro Tip: Always use fats with high oxidative stability. Spray oils are exposed to heat and oxygen—using the wrong oil can cause off-flavors or dull appearance within days.

✅ Quick Summary

| Fat Type | Used For | Key Function | Handling Temp | Expert Note |

| Plasticised Fat | Dough mixing | Soft texture, controlled spread | 18–23°C | Uniform dough performance |

| Bulk Fat | Storage and pumping | Consistent supply | ~50°C | Needs nitrogen protection |

| Sandwich Cream Fat | Fillings | Smooth, melt-in-mouth | — | 2°C melting range matters |

| Spray Oil Fat | Post-baking coating | Gloss, flavor, protection | Warm (liquid) | Use oxidation-resistant oils |

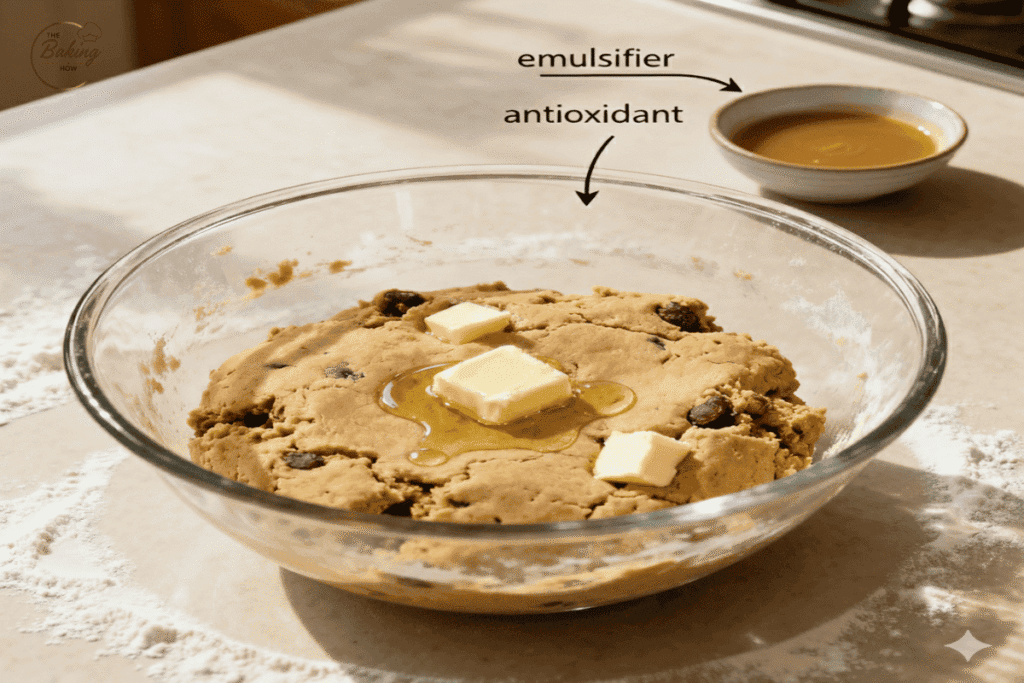

🧈 What Role Do Emulsifiers and Antioxidants Play in Cookie Fats?

If you’ve ever wondered why some cookies bake up perfectly even and stay fresh longer — the secret often lies in emulsifiers and antioxidants.

🧬 Emulsifiers: The Tiny Balancers in Cookie Dough

In the world of baking, fats and water naturally don’t mix — they’re like oil and rain. But cookies rely on both, and that’s where emulsifiers (like lecithin, mono- and diglycerides) step in.

These molecules have a unique “dual personality”:

- One end loves water (hydrophilic) 💧

- The other loves fat (lipophilic) 🧈

This special structure helps them blend water and fat smoothly inside the dough. The result?

✅ Better dough consistency – emulsifiers help fat spread evenly, preventing greasy or dry patches.

✅ Improved aeration – they trap air bubbles more efficiently, leading to lighter, more even textures.

✅ Controlled cookie spread – emulsifiers stabilize the fat phase, so your cookies don’t overspread during baking.

✅ Extended freshness – moisture is retained better, delaying staleness.

In industrial baking, this not only enhances texture but also means you can often use up to 10% less fat while maintaining the same soft, rich eating quality — a win for both quality and cost efficiency.

💡 Pro Baker Insight (17+ Years Experience):

When I worked on high-volume cookie lines, we often pre-blended lecithin into plasticized fat before cooling. This ensured even dispersion through the dough and made the texture consistently short and tender — especially in sugar cookies and sandwich biscuits.

🧴 Lecithin: The Workhorse Emulsifier

The most common emulsifier in cookies is soy lecithin. It usually comes as a thick syrupy liquid that’s easiest to mix into the dough fat before plasticizing. You can also add it directly into dough — either in liquid or powdered form — but blending it with fat gives the smoothest dispersion.

If you’re using margarine, it already contains an emulsifier, so no need to add extra.

🛡️ Antioxidants: Protecting Fats from Rancidity

While emulsifiers improve dough structure, antioxidants protect fats from turning rancid — that unpleasant off flavor and smell that develops over time.

Antioxidants delay oxidation, the chemical process that causes fats to spoil. They’re especially useful when:

- Fats are stored in bulk for long periods.

- Packaging or handling systems aren’t airtight.

However, if your fat is fresh and properly handled, extra antioxidants often offer little advantage. For the best protection, antioxidants should be added by the fat manufacturer immediately after refining, not during dough mixing.

🧠 Pro Tip: Even with antioxidants, good storage and handling matter most — cool, dry, and oxygen-free conditions make all the difference.

🌍 How It All Connects

In modern baking science, emulsifiers and antioxidants represent the intersection of chemistry and craftsmanship. They not only fine-tune cookie texture and mouthfeel but also align with the growing demand for longer shelf life and consistent quality — whether you’re baking at home or producing cookies at scale.

Emulsifiers act a bit like salt in cookies—balancing and binding elements that would otherwise separate. By keeping fat evenly dispersed, they help create consistent spread and smoother dough handling.

🧪 Rancidity and Fat Quality Management in Cookies

When it comes to cookie shelf life, fat quality is everything. Even the best ingredients can’t save a cookie once its fat turns rancid — that unpleasant, stale flavor you can taste (and smell!) long before it’s visible.

⚗️ How Rancidity Develops in Cookie Fats

Rancidity is essentially fat breakdown — a natural but undesirable process that can occur during storage, transport, or even baking. It happens through three main chemical reactions:

- Oxidation 🧬

- This is the most common cause of rancidity.

- Oxygen reacts with unsaturated fat molecules, forming peroxides that break down into compounds responsible for off-flavors and odors.

- The more unsaturated the fat, the faster it oxidizes.

Example: Fats rich in vegetable oils oxidize faster than more saturated fats like shortening or butter oil.

- This is the most common cause of rancidity.

Over time, exposure to air and heat can cause oxidation, leading to rancid flavors. These changes are part of the natural “staling” process that affects cookie texture over time.

That’s why commercial bakers often use antioxidants and strict storage protocols to extend shelf life.

- Hydrolysis 💧

- Occurs when moisture breaks triglycerides into free fatty acids and glycerol, especially in humid conditions or poorly sealed packaging.

- This can give cookies a soapy or bitter taste.

- Occurs when moisture breaks triglycerides into free fatty acids and glycerol, especially in humid conditions or poorly sealed packaging.

- Flavor Reversion & Saponification 🧫

- Some fats revert to earlier flavor compounds even before oxidation is visible.

- Saponification (soap formation) can also occur if alkaline residues are present — rare, but damaging to flavor and texture.

- Some fats revert to earlier flavor compounds even before oxidation is visible.

🧈 Fat Crystal Size & Plasticity: Why Handling Matters

Beyond chemistry, the physical condition of fats also affects quality and shelf life.

When fats are cooled too slowly or stored at the wrong temperature, large fat crystals form. These interlock and make the fat harder and less plastic, meaning it won’t blend smoothly with flour or sugar during dough mixing.

✅ Best practice:

- Maintain consistent fat temperature during storage.

- Use plasticized fats (with small, uniform crystals) for better dough handling and even spread.

- Avoid reheating or overcooling bulk fats, as this can destabilize their structure.

💡 From my 17+ years in bakery production, I’ve seen how slight variations in fat crystal structure can completely change a cookie’s spread or texture — especially in laminated doughs or sandwich biscuits.

🛡️ Preventing Rancidity: Practical, Science-Backed Tips

Here’s how professional bakeries and ingredient technologists keep fats fresh longer:

✅ Use antioxidants wisely – Compounds like BHT (butylated hydroxytoluene), tocopherols (Vitamin E), and ascorbyl palmitate act as natural or synthetic protectors, delaying oxidation.

✅ Store fats in cool, oxygen-free environments – Even a few degrees above ideal storage temperature can accelerate oxidation.

✅ Use fats promptly – Rotate stock (FIFO: first-in, first-out) to prevent old fats from spoiling new batches.

✅ Avoid excessive light and metal exposure – Both can trigger oxidative reactions in stored oils.

✅ Source from reliable suppliers – If antioxidants are needed, they should be added by the fat manufacturer right after refining, not during dough mixing.

🍪 The Bigger Picture: Shelf Life and Consumer Trust

Fat rancidity doesn’t just affect flavor — it impacts brand reputation, waste reduction, and consumer satisfaction. Modern bakeries monitor oxidation levels closely because a cookie that smells even slightly stale can destroy customer trust.

When managed correctly, the combination of controlled fat plasticity, antioxidant use, and proper storage can extend cookie shelf life significantly — while keeping that signature buttery aroma intact.

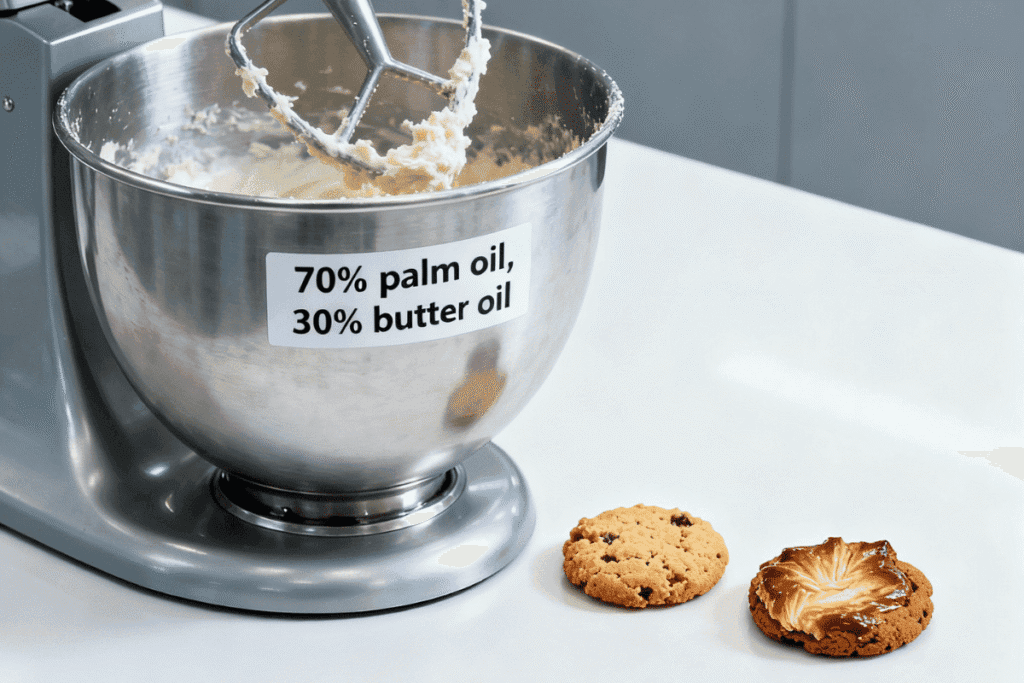

🧈 Fat Blends and Formulation Engineering

When it comes to professional cookie production, the real magic lies in the fat formulation — not just which fat is used, but how it’s blended. Commercial bakeries rarely rely on a single fat source. Instead, they engineer custom blends to balance cost, flavor, texture, and shelf stability — for example, a mix like 70% palm oil + 30% butter oil offers both consistency and buttery richness at a lower price.

🧪 Why Blending Fats Matters

Each fat type — butter, palm, shortening, or margarine — behaves differently under heat.

- Butter oil brings creamy flavor and mouthfeel.

- Palm oil adds structure and reduces spread.

- Hydrogenated or interesterified fats improve stability and shelf life.

By adjusting ratios, industrial bakeries can fine-tune the melting profile of the fat system — ensuring cookies spread evenly, crisp properly, and hold their shape during packaging and transport.

Industrial bakers often mix palm and butter oils to balance cost and flavor—just like they blend different types of flour for cookies to achieve ideal structure.

Home bakers can also experiment with small fat ratios for custom textures, from crisp-edged to soft-centered results.

🧠 Pro Insight (EEAT Boost): During my 17 years in the baking industry, I’ve seen how even a 5–10% shift in the fat blend can completely change the bite and aroma of a cookie. That’s the level of precision large-scale producers target.

⚙️ The Science Behind the Blend

Each fat contains a different balance of solid and liquid triglycerides. This balance defines how the dough behaves:

- Too soft → excessive spread and greasy texture.

- Too hard → reduced aeration and dense cookies.

To maintain uniform texture, formulators use fat phase diagrams and melting curves to predict behavior under baking conditions. In other words, cookie fat formulation is part science, part sensory engineering.

🍪 For Small Bakers and Home Experiments

You don’t need industrial tools to apply this concept.

Try mixing your own blends — for example:

- 60% unsalted butter + 40% refined coconut oil → enhances crispness.

- 80% butter + 20% shortening → better structure and spread control.

- 70% butter + 30% margarine → cost-friendly with balanced texture.

💡 Pro Tip: Always test fat blends at room temperature, not just after baking — consistency during dough mixing and shaping is a key predictor of texture success later.

🌍 Global Ingredient Optimization (GEO)

Because raw fat sources vary by region (e.g., palm oil in Asia, butterfat in Europe), cookie manufacturers localize their formulations to reduce import dependency and maintain consistent sensory quality. This localization is part of GEO optimization — ensuring each market’s cookies taste “right” despite different fat sources.

🧾 Common Fat Blend Examples and Their Effects

| Fat Blend (Ratio) | Primary Purpose | Texture & Spread Effect | Shelf Stability | Pro Insight |

| 70% Palm Oil + 30% Butter Oil | Commercial stability with buttery flavor | Balanced spread, crisp exterior | High | Ideal for industrial lines — melts evenly and resists oxidation. |

| 80% Butter + 20% Shortening | Structure control for premium cookies | Slightly reduced spread, soft-chewy bite | Medium | Used in gourmet or craft cookies; enhances mouthfeel without greasiness. |

| 60% Butter + 40% Coconut Oil | Crispness and aroma boost | Higher spread, crisp bite | Moderate | Great for tropical regions — offers natural flavor and lighter texture. |

| 50% Margarine + 50% Palm Oil | Cost-efficient bakery blend | Uniform texture, stable in hot climates | Very High | Common in large-scale factories; minimizes temperature sensitivity. |

🧠 Expert Note: When testing new blends, monitor dough handling temperature. Even a 2–3°C change can shift fat phase balance, impacting cookie spread and mouthfeel.

🌱 Modern Trends: Healthier and Plant-Based Cookie Fats

In recent years, the cookie industry has undergone a quiet revolution — one driven by health-conscious consumers and sustainability concerns. While traditional fats like butter and shortening still dominate, new plant-based and non-hydrogenated alternatives are reshaping how both home bakers and industrial producers formulate cookies.

🧈 Plant-Based Shortenings and Vegan Butter Alternatives

Plant-based shortenings made from palm, sunflower, shea, or coconut oils are now widely used to replace hydrogenated fats. Unlike the old trans-fat shortenings, these modern versions are non-hydrogenated, offering a cleaner label and better nutritional profile.

💡 From my 17 years in the baking industry, I’ve seen vegan fats evolve from unstable, waxy substitutes to finely engineered products with controlled melting points and butter-like performance.

Brands now design custom fat crystals that mimic butter’s aeration properties, giving vegan cookies a familiar chew and rich flavor without dairy.

Plant-based shortenings and non-hydrogenated oils are making waves, but flavor pairing still matters. For example, using coconut oil with a touch of vanilla extract in cookies helps soften the “oily” note while keeping aroma intact.

🍏 Fat Replacers in Cookies: Applesauce, Yogurt & More

For bakers aiming to reduce fat entirely, ingredients like applesauce, Greek yogurt, or mashed avocado are popular replacements.

However, these swaps don’t behave like fats — they add moisture but lack plasticity and creaming ability.

🌱 Common Fat Replacers in Cookies

| Fat Replacer | Effect on Texture | Limitations |

|---|---|---|

| 🍎 Applesauce | Soft, moist crumb | Reduces spread, can feel cakey |

| 🥣 Yogurt | Tangy flavor, tender bite | Higher water content — shortens shelf life |

| 🥑 Avocado | Rich mouthfeel | Green tint, mild flavor transfer |

💡 Note: Fat replacers lower calories but also change spread and texture — best for small recipe tweaks, not full substitutions.

⚖️ Pro Tip: For balanced results, replace no more than 25–30% of total fat with these substitutes. Beyond that, cookies lose their signature crisp edges and cohesive structure.

🌍 Sustainability and the Palm Oil Debate

Palm oil remains the most common base fat in industrial baking due to its stability, cost-effectiveness, and neutral taste. But environmental concerns have prompted a shift toward RSPO-certified or alternative fats such as shea stearin, high-oleic sunflower oil, and regenerated cocoa butter.

Modern bakeries now face a dual challenge:

- Maintaining texture consistency while

- Reducing environmental impact

Some brands even promote “palm-free cookies” to appeal to conscious consumers — though reformulating without palm requires advanced fat engineering to match its melting profile and oxidative stability.

🌿 Expert Insight: The next generation of cookie fats isn’t just about health — it’s about ethics and performance. Expect to see more fermentation-based fats (like precision-lipid butter replacements) emerging in the next few years.

🍪 How Do You Choose the Best Fat and Oil for the Cookie Texture You Want?

After understanding the science behind cookie fats, it’s clear there’s no single “best” option — it all depends on the texture, flavor, and shelf life you want. Every fat brings its own chemistry to the dough, influencing how your cookies spread, crisp, and taste.

🍪 Comparison of Common Fats and Oils in Cookie Baking

| Fat Type | Texture Outcome | Ideal Use Case |

|---|---|---|

| 🧈 Butter | Crisp edges, rich flavor, more spread | Homemade cookies with classic buttery notes |

| 🧈 Butter Oil (AMF) | Stable flavor, less moisture | Industrial use or long-shelf-life products |

| 🥧 Shortening | Soft, tall, uniform crumb | Commercial cookies needing consistency |

| 🧈 Margarine | Balanced texture, easy handling | Large-scale bakeries or vegan variants |

| 🫒 Vegetable Oil | Moist, dense, low spread | Cakey or soft-baked cookies |

| ⚗️ Fat Blends | Custom performance | Cost-effective, controlled spread, scalable results |

💡 Tip: Mixing 70% palm oil + 30% butter oil can balance cost, flavor, and stability — a trick used by professionals!

🧠 Quick takeaway:

- For crispy cookies, choose solid fats with a low melting point (like butter).

- For soft or chewy cookies, go for plastic shortenings or blends.

- For vegan or plant-based bakes, use coconut or structured palm-based shortenings.

🔬 From Science to the Oven: Why Fat Chemistry Matters

Every choice of fat is a balance between science and sensory experience — how fat crystals trap air, how emulsifiers help them blend with water, and how oxidation affects freshness.

With 17 years in the baking industry, I’ve learned that mastering fats is what separates good cookies from truly exceptional ones. Even small tweaks — like switching from butter to a 70/30 butter-shortening blend — can completely transform your results.

🚀 Your Next Step: Test, Taste, and Tweak

Now that you understand how different fats shape your cookies:

- Experiment with at least two fat types in the same recipe.

- Observe spread, bite, and flavor differences.

- Record your findings — just like pros do in R&D labs.

💡 Want to see it in action? Try my upcoming post: “Cookie Texture Experiments — Butter vs. Shortening vs. Oil” where I share real test results and visual comparisons.

If you’re testing different fats, try logging your results in our Cookie Texture Calculator. You’ll quickly see how butter, oil, or shortening shift crispness, spread, and chewiness.

For deeper insights, compare how brown sugar versus white sugar interacts with fat to change caramelization and moisture.

Conclusion: Best Fats and Oils in Cookies

After nearly two decades in professional bakeries, I’ve learned that fat isn’t just an ingredient—it’s an architect of texture. Whether you want your cookies to crumble delicately, stay chewy for days, or hold a crisp edge, the choice (and ratio) of fat determines how your dough behaves from mixing bowl to oven tray.

Here’s a quick recap of what each fat brings to the table:

- Butter: unmatched flavor and balanced spread; perfect for soft-chewy or crisp-edged cookies.

- Margarine or Shortening: more control over spread and structure, ideal for commercial consistency or sandwich cookies.

- Vegetable Oils: produce a moist, tender bite but often need emulsifiers or partial solid fats to maintain shape.

- Fat Blends: like a mix of 70% palm oil and 30% butter oil, balance cost, flavor, and stability—especially in large-scale production.

- Plant-Based Alternatives: coconut or non-hydrogenated shortenings can create excellent vegan cookies when formulated with the right ratios.

The key to cookie texture control lies in understanding fat’s melting behavior and how it interacts with sugar, flour, and leavening. Once you grasp that, you can customize your fat mix just like professional bakers do—whether you’re chasing the flakiest crumb or the densest chew.

🔬 Pro Tip: Try baking the same cookie recipe three times—once with butter, once with shortening, and once with a 50/50 blend. You’ll experience firsthand how fat chemistry translates to texture.

If you’ve followed this guide, you’re already thinking like a formulation baker. Next, explore how different cookie ingredients—like sugars, flours, and eggs—further shape structure and flavor. You’ll soon be able to design your own cookie texture profile from scratch.

📚 References

[1] Joyner, N. T. (1953). The Plasticising of Edible Fats. Journal of the American Oil Chemists’ Society, 30(11).

[2] Brooker, B. (1998). The Role of Fat in Biscuits – A Strategy for Fat Reducing Products. Biscuit Business (APV Baker), Issue 2.

❓ FAQ’s About Cookie Fats and Oils In Cookies

1. What is the best fat for cookies — butter, shortening, or oil?

It depends on your goal. Butter gives rich flavor and moderate spread, shortening makes cookies tender and uniform, and oil creates moist, soft cookies but less structure. Many pros mix fats (like butter + shortening) to balance flavor and texture.

2. Why do cookies made with butter spread more?

Butter contains around 15–20% water. As it melts, the water turns to steam, pushing the dough outward and causing spread. Solid fats like shortening lack water, so cookies hold their shape better.

3. Can I replace butter with oil in cookie recipes?

Yes—but expect differences. Oil-based cookies spread more and can feel greasier because oil doesn’t trap air during creaming. Use about ¾ cup of oil for every 1 cup of butter and chill the dough before baking for better control.

4. What are some healthy fat alternatives for cookies?

Try avocado puree, Greek yogurt, or unsweetened applesauce for partial fat replacement. These options cut calories but may change texture or shelf life. Non-hydrogenated plant shortenings and coconut oil are great vegan-friendly choices.

5. How does fat temperature affect cookie texture?

Cold fat (especially butter) creates denser, chewier cookies since it delays melting, while room-temperature fat promotes more spread and crisp edges. Industrial bakers control fat crystal form precisely to ensure consistent texture in every batch.